Industry 4.0

Our Industrial team always at the forefront of technology, design and continuous improvement, marked by INDUSTRY 4.0, taking on Industrial Plant projects in any sector independently or in coordination and complementing itself with the rest of our Civil and building engineering, Mechanics and Architecture to carry out industrial projects from start to finish.

CADBIM experts and always up to date on INNOVATION, working on projects at the National and International scope with collaborative software such as BIM360 to maintain a strong communication level with our client from anywhere. We adapt ourselves to the initial information received from the client; a 2D drawing, a P&ID, SCAN TO BIM modeling or POINT CLOUD.

Our motto is to maintain closeness with our clients to understand their business, meet their needs and thus offer excellence in service.

1. BIM SERVICES

To guarantee our closeness and communication wherever our client is, we have cutting edge technology and software such as BIM 360, optimizing our performance from anywhere in the world.

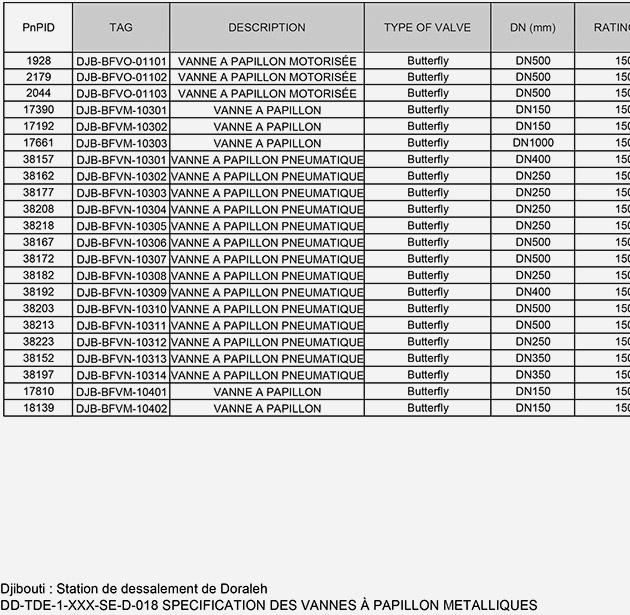

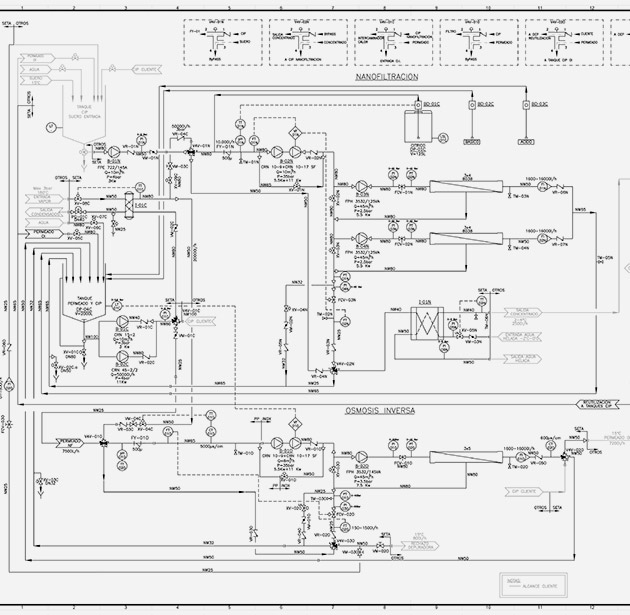

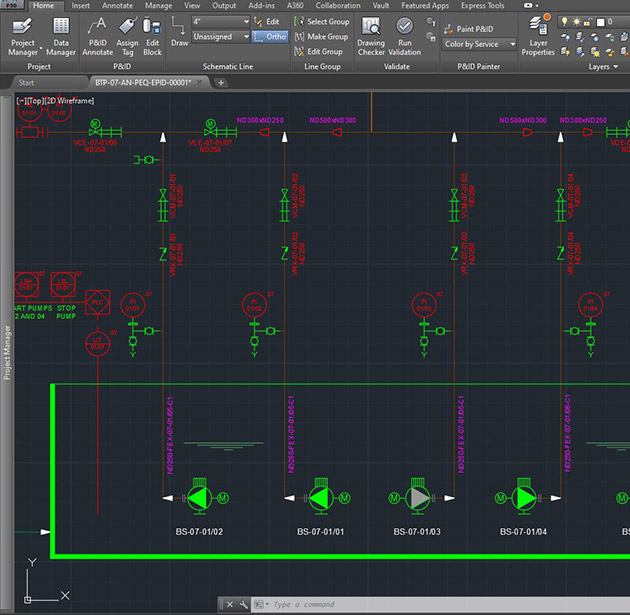

P&ID

We take on complex projects based on P&ID (Piping and Instrumentation Diagram / Drawing) which show us the flow in the pipes, equipment and instruments. The symbols allow us to identify all the components of the process (pipes, number of pipe lines and their dimensions, valves, controls, alarms, equipment, levels, pressure switches, drains, purgers, pumps, etc.) of which extract information such as:

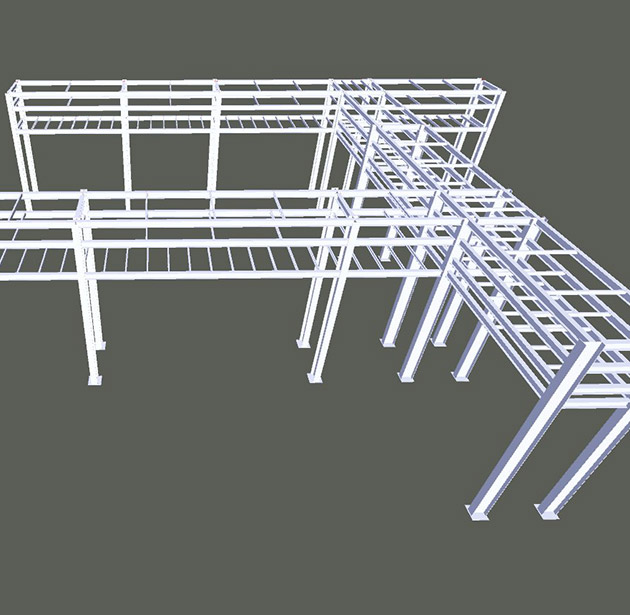

CIVIL WORKS AND STRUCTURES

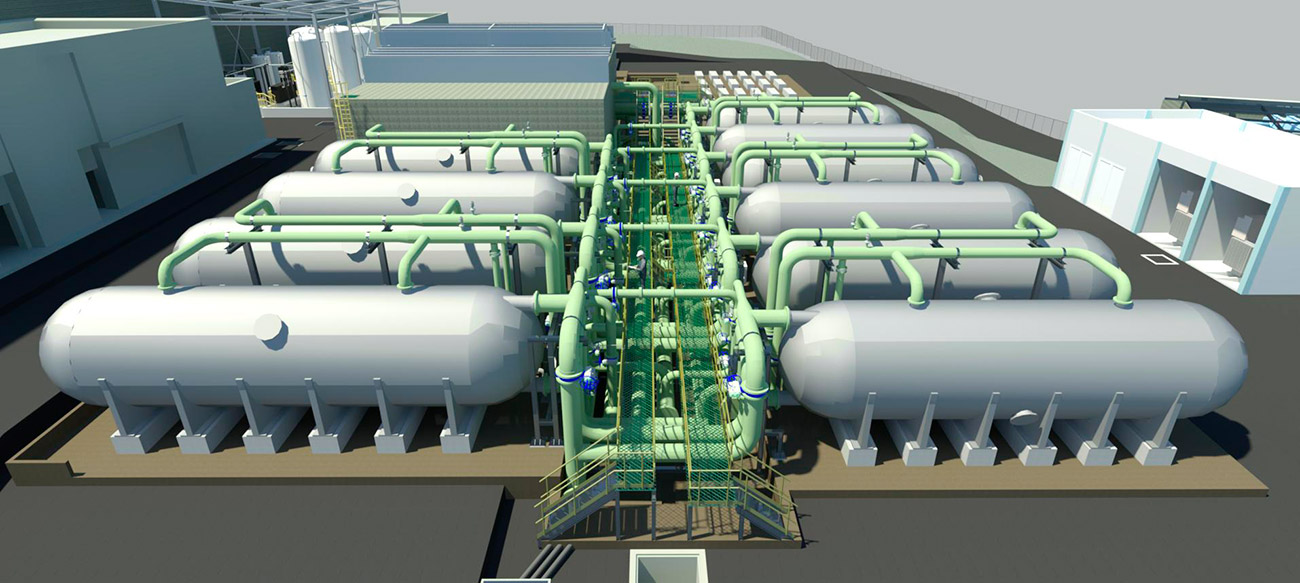

We define the project in 2D and build the 3D model. Depending on the sector, it could be roads, equipment, pipe racks, concrete dies for pipe supports, structural foundations, drainage pits, circular decanters, biological reactors, digesters, industrial buildings, control offices, etc, providing us with the base to further develop the other disciplines such as:

MECHANICAL EQUIPMENT

We model all the equipment inside industrial plants in any sector and detailed equipment to be able to define accurate connections and have the general dimensions to implement them in the process in the most optimal way. We also covert equipment suppliers 3D modelts into different formats, source format of the pipe design program we use.

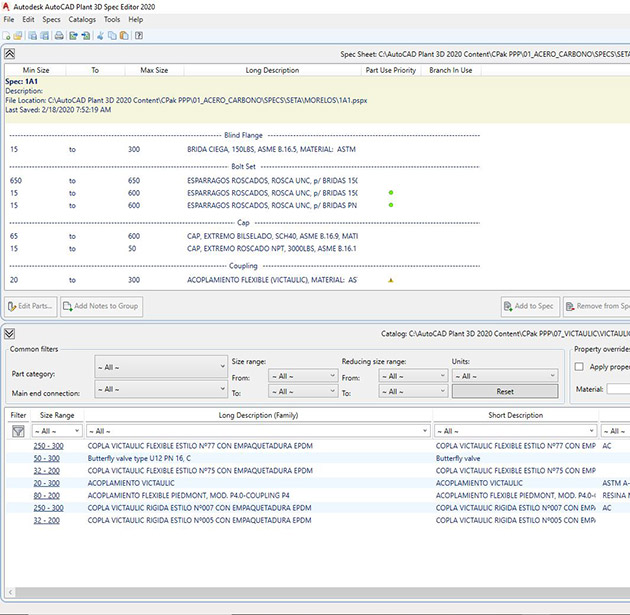

ADMINISTRATION AND DEVELOPMENT OF CATALOGS AND SPECIFICATIONS:

Our Program ADMINISTRATORS are in charge of making the correct configuration before the 3D pipe design begins. Using programs like AutoCAD PLANT Spec Editor to create CATALOGS and SPEC, counting with a large catalogs and specifications library based on different suppliers and design standards:

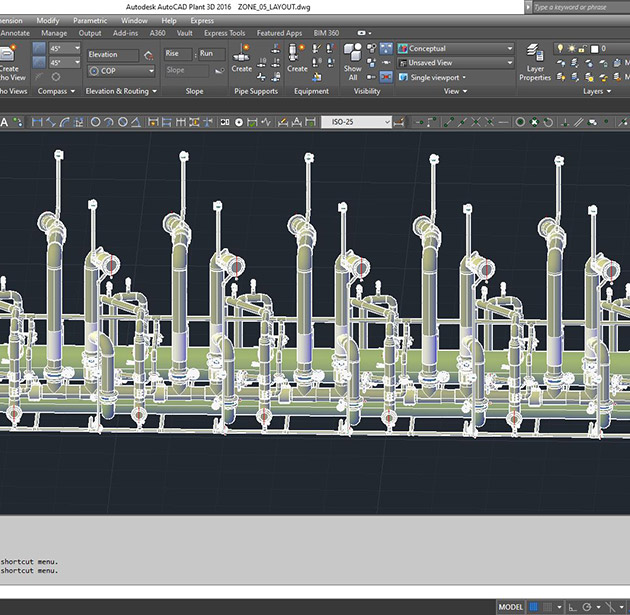

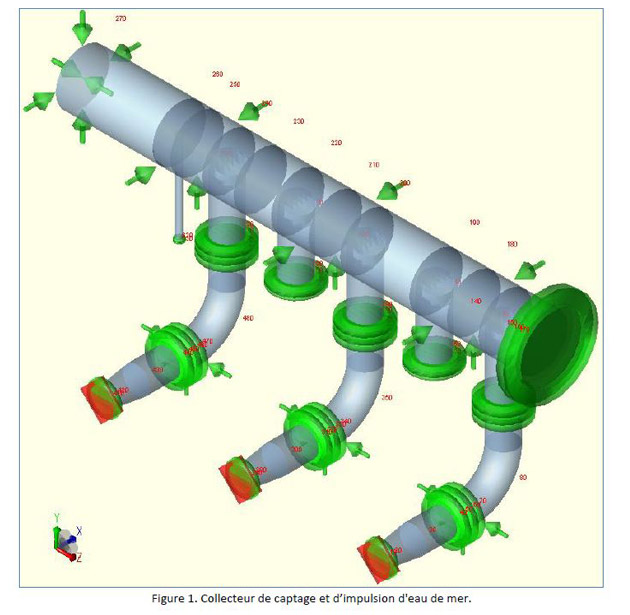

PIPING AND SUPPORT MODELING:

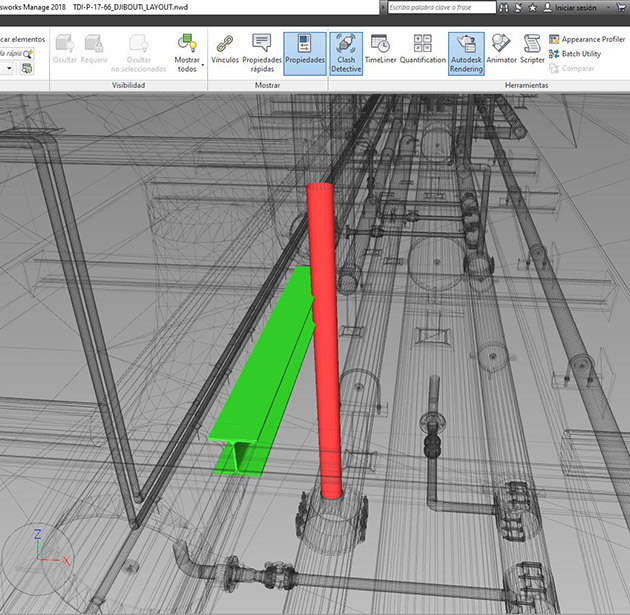

Our highly qualified BIM modelers are able to carry out designs and pipes routing in the most optimal way, always having assembly, maintenance, costs and aesthetics in mind. We design and implement in the 3D model the supports according to the client’s standard, or make our own designs based on the regulations and pipe supports separation. Avoiding and correcting possible clashes in the virtual model to save time and material costs for our clients.

INSTRUMENTATION AND CONTROL (I&C)

The modeling process includes detailed instrumentation and control, generating very precise documentation necessary to systematize and control processes in the plant. We generate documentation like:

ELECTRICAL INSTALLATIONS:

Implementing other 3D design software, our Industrial team can include electrical elements such as:

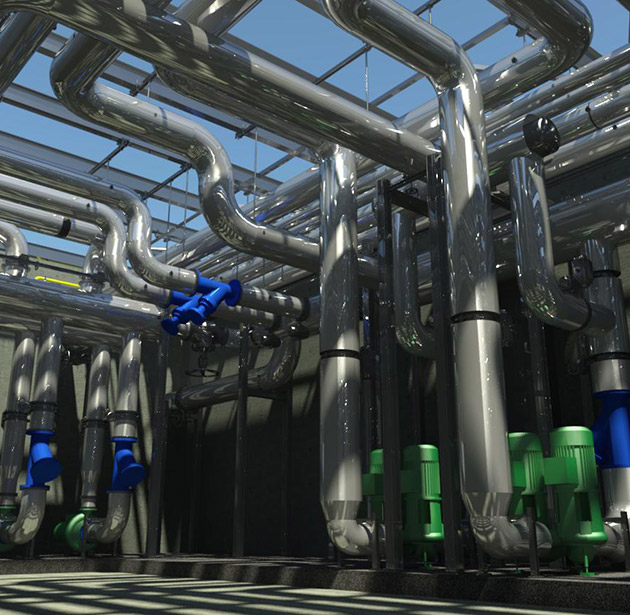

3D MODEL:

Experts in creating interactive 3D models with integrated information on each element. Thanks to the interconnection between all project parts, we run clash analyses reporting them to correct them subsequently in the virtual model saving time and cost during the construction phase.

EQUIPMENT, PIPES, SUPPORTS AND ELECTRIC TRAYS IMPLEMENTATION:

All 2D project documentation is based on the 3D model. These drawings define elements geometry to detail with dimensions and tags.

ISOMETRIC:

Pipes isometric drawings are one of the most important within the projects, so our clients could perfectly manufacture the pipe SPOOL to reduce costs on site. We adapt ourselves to any kind isometric format configuration to ensure that we perfectly meet our client’s expectation.

MATERIALS LISTINGS:

From the 3D models, we generate material collection schedules to speed up and make our client’s Purchasing Department’s work easier. These lists come with enough information to purchase materials with a minimum waste, since the schedules contain exact quantities of each material.

STRESS CALCULATIONS, HAMMER AND SUPPORT:

To ensure that the piping system final design is viable, reliable, optimal and safe, we carry out STRESS CALCULATIONS and analyse the inherent FLEXIBILITY of the piping system, thus defining a correct SUPPORTING strategy. Committed to safety within our installation projects, we always include water hammer studies ensuring correct operation with the stress of the pipes and their supports, no matter how simple the pipe system seems.

2. SPECIALISTS IN WATER TREATMENT

Specialists in ENVIRONMENTAL, PETROCHEMICAL and SANITARY SECTOR projects, we pride ourselves on helping the environment to eliminate or reduce water pollution.

3. INDUSTRIAL PLANTS MODELING

BIM technology, design and detailed engineering of new facilities or modernization of industrial complexes.

4. FACILITY PROJECTS

Specialized in FIRE PROTECTION and industrial facilities such as Electrical and Mechanical, from Industrial Plants to industrial surface projects for industry, storage, manufacturing, retail.

5. OUTSOURCING AND RECRUITMENT

We are experts in talent acquisition. We have been selecting the best profiles for our team over a decade, training them and enhancing their value to maintain our quality standards and service excellence.

Outsourcing. We join your team for as long as you need.

Selection. We offer you our selection and recruitment service with the same commitment and dedication as if we did it for our team.